I have a 2019 Ram Promaster 3500 Ext with the upgraded 220A alternator (sales code BAJ, Mopar part # 68271770AA.) I am using a Renogy 50A DC to DC Charge Controller and need to know if my alternator is Smart (variable voltage alternator) or a traditional alternator in order to properly install the Renogy DC to DC charger. No luck from RAM, Promaster, or Mopar in getting an answer.

Smart Alternator

1 reading

41 - 57 of 57 Posts

I can add that it's the exact same 220 alternator that I have. Mopar says it fits 2014-2021 (at least). I also have a Renogy DC-DC. I did not treat it like a smart alternator. I just hooked up the D+ wire to an ignition-on source like it was a dumb alternator and it's been working fine for years now. Several others on this forum have done the same thing with the same results.I have a 2019 Ram Promaster 3500 Ext with the upgraded 220A alternator (sales code BAJ, Mopar part # 68271770AA.)

BTW, the graph in post #41 above doesn't show variable voltage. It shows variable amperage at a constant voltage (14.0V), as a function of alternator RPM (not the same as engine RPM).

So perhaps the divergence between RAM's answer and empirical evidence from @N4Adventure and @larry barello lies in the notion that the PM generator itself is capable of being smart (variable output) but the electrical software does not allow it to perform in this smart mode?

I'm just glad it works

Thank you for that link. I’ve wondered about “smart alternators” and that really helped.Almost spit out my coffee. The Dark Lords answer no one, pilgrim. On the other hand, @Jing knows his caca, electrically speaking. Attached link has an explanation of what a smart alternator is and an easy test for determining if you have one or not. (Spoiler alert: You don't.)

What is a smart alternator and have I got one?

What is a smart alternator and do I have one? This article is an updated version of our hugely popular 4 step simple smart alternator test. I hope you find it useful. Smart alternators are something that’s coming up more and more frequen...rayneautomotivehelp.freshdesk.com

Joined

·

118 Posts

You only get 25 amps from the alt and 25 from solar so if you have both going then youll get 50 a maybe.You need to get a plug for the b pillar electrical and find the one terminal to attach it to .At least thats what I did.Dont probe the terminal you can put a fault into the computer.Research Will Prowse Videos .The Yeti 1000Ii have wont power a webasto .either.Neophyte here, at least when it comes to all things electrical, especially in terms of vehicle electronics. So be kind, please. I have read through this thread so far and find it all fascinating, at least as far as I can understand it. And I just happen to have an issue that I'd love to solve with a DC2DC charger.

Here's my setup:

Here's are my questions:

- 2019 PM 1500 (136", short height, DIY camper conversion)

- I assume a "non-smart" standard alternator, 180A (but I will use the @Jing link that @HippieGypsy provided to run the test and make sure)

- I have an old(er) Goal Zero Yeti 1000 that I use for my house battery

- I'm really having trouble with the 12V accessory socket charger that I bought from Goal Zero: the "connection" comes and goes and I don't know if it's the 12V socket or the Goal Zero that's having the problem. It charges just fine from a portable solar panel.) Anyway...

- I am considering the purchase of the YetiLink Vehicle Integration Kit which I guess is a basic DC2DC charging kit.

Does anyone have any experience with the YetiLink Vehicle Integration Kit?

It sells for $449 and comes with the instruction that it must be installed by a licensed professional.

Would the Renogy 50A DC2DC Charge Controller work just as well? Or maybe better?

This seems to be the product choice for many PM Forum members.

Am not sure if the product comes with all the additional wire, connectors, etc. that would be required for installation.

I'd probably have to get a "licensed professional" to install for me as well.

Does adding a DC2DC charger affect MPG? Somewhat? Significantly?

What other questions should I be asking? What other issues might I need to address?

Thanks so much in advance for your help with this!

Ditto. I have the same setup and all the controls suggested above. In addition, DC-DC system has a delayed start only when the both the ignition key is on and the supplied voltage is over 13.6. See: Renogy 60A DC-DC charger in 2016 Pleasureway - Class B ForumsVery true! I have the 220A alternator and a 60A Renogy DC-DC. No special smart-alternator procedure used or needed. While you are at it, do yourself a favour and install an on/off switch in the D+ wire so you have manual control. Adding an optional LC+ wire to the same D+ power feed, with its own switch, lets you charge at half-power (30A) when you're not in a hurry and feel like giving the alternator a break.

My 2021 has the 220 amp alternator and I've noticed the charging voltage varying from 13.6 volts to 14.6 volts when checking my starter battery on the Victron Connect app while driving. The three times I monitored it the charging voltage would start out at a given voltage and stay at that voltage over my 20 mile drive. Presumably the Big Computer is controlling this.

The alternator on my 2000 Ford van would start charging at 14.8 volts or so after a cold start then slowly drop down to 14.4 volts or so as the battery recharged as I drove so the "new technology" RAM charging algorithm appears to be a bit of a different animal.

The alternator on my 2000 Ford van would start charging at 14.8 volts or so after a cold start then slowly drop down to 14.4 volts or so as the battery recharged as I drove so the "new technology" RAM charging algorithm appears to be a bit of a different animal.

The Promaster alternator is controlled by the van's computer. It uses a current and temperature sensor on the battery to change the alternator output/voltage. It's not a "smart" alternator by the definition of B2B manufacturers but it is computer controlled. It depends on battery condition and temperature but generally stays in a battery friendly voltage range that allows for split charging and voltage activated B2B chargers.

IMO it works really well. It won't let the smoke out like that staged Victron video and it doesn't play games that are hard on the battery to fool the EPA numbers. The voltages on our van are spot on to keep a lead acid battery at 100% SOC without overcharging.

Here's an article on how it works:

Test of ECU-controlled charging system

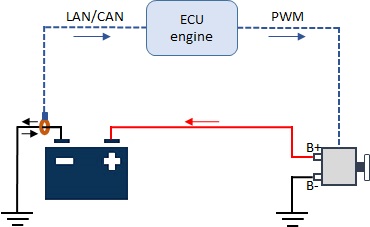

An ECU-controlled alternator test is carried out on modern vehicles where there is an intelligent power supply control system. An electronic control unit (ECU) controls the alternator operation. ECU monitors the needs of the vehicle’s electrical system and, based on that, can regulate the output voltage alternator within wide limits (12.7 – 15.5 V) via the rotor power supply. Also, ECU can increase engine idle speed when the alternator is overloaded.

The engine ECU controls the operation of the alternator based on the data obtained from the sensor on the minus terminal of the battery. The sensor on the minus terminal is in the form of a current clamp (Hall sensor) that encompasses the minus cable or the voltage divider (shunt) on the terminal and measures the strength of the charging and discharging current of the battery. It often contains a temperature sensor and can measure the battery temperature. It sends data to the engine ECU via the LIN or CAN network.

![Battery current sensors Battery current sensors]()

Battery current sensors in the form of current clamps or voltage dividers

The ECU engine determines the current state of the power system based on data on the size of the charging and discharging current, the network voltage, and the battery temperature (measured or estimated). It recognizes several modes and regulates the power supply to the rotor windings using PWM. The size of the PWM power supply determines the strength of the magnetic field and the size of the alternator output voltage.

![Image]()

ECU-controlled alternator

When the error light comes on or the operation of the power supply system is suspected, diagnostics are first performed by reading the error codes. If errors are stored, based on the error code and operating instructions, we approach finding the fault. The check can include the alternator, the current sensor, the wires with the connectors, the battery, and finally the ECU engine.

The output voltage from the alternator, battery charge and discharge current, PWM regulation, sensor power, and ECU condition can be checked by measurement. All parameters are monitored via the actual values on the diagnostic device which are visible from the ECU side. In parallel, the same parameters are measured with measuring devices such as an ammeter (current clamp), voltmeter, and oscilloscope recording of PWM signals.

![Relationship between PWM regulation and alternator output voltage Relationship between PWM regulation and alternator output voltage]()

Relationship between PWM regulation and alternator output voltage

Based on the instructions for checking, diagnostics, reading the actual values on the diagnostic device, measuring the current and voltage, and recording the signal, the condition of the power supply system is determined and the malfunction is detected.

IMO it works really well. It won't let the smoke out like that staged Victron video and it doesn't play games that are hard on the battery to fool the EPA numbers. The voltages on our van are spot on to keep a lead acid battery at 100% SOC without overcharging.

Here's an article on how it works:

Test of ECU-controlled charging system

An ECU-controlled alternator test is carried out on modern vehicles where there is an intelligent power supply control system. An electronic control unit (ECU) controls the alternator operation. ECU monitors the needs of the vehicle’s electrical system and, based on that, can regulate the output voltage alternator within wide limits (12.7 – 15.5 V) via the rotor power supply. Also, ECU can increase engine idle speed when the alternator is overloaded.

The engine ECU controls the operation of the alternator based on the data obtained from the sensor on the minus terminal of the battery. The sensor on the minus terminal is in the form of a current clamp (Hall sensor) that encompasses the minus cable or the voltage divider (shunt) on the terminal and measures the strength of the charging and discharging current of the battery. It often contains a temperature sensor and can measure the battery temperature. It sends data to the engine ECU via the LIN or CAN network.

Battery current sensors in the form of current clamps or voltage dividers

The ECU engine determines the current state of the power system based on data on the size of the charging and discharging current, the network voltage, and the battery temperature (measured or estimated). It recognizes several modes and regulates the power supply to the rotor windings using PWM. The size of the PWM power supply determines the strength of the magnetic field and the size of the alternator output voltage.

ECU-controlled alternator

When the error light comes on or the operation of the power supply system is suspected, diagnostics are first performed by reading the error codes. If errors are stored, based on the error code and operating instructions, we approach finding the fault. The check can include the alternator, the current sensor, the wires with the connectors, the battery, and finally the ECU engine.

The output voltage from the alternator, battery charge and discharge current, PWM regulation, sensor power, and ECU condition can be checked by measurement. All parameters are monitored via the actual values on the diagnostic device which are visible from the ECU side. In parallel, the same parameters are measured with measuring devices such as an ammeter (current clamp), voltmeter, and oscilloscope recording of PWM signals.

Relationship between PWM regulation and alternator output voltage

Based on the instructions for checking, diagnostics, reading the actual values on the diagnostic device, measuring the current and voltage, and recording the signal, the condition of the power supply system is determined and the malfunction is detected.

Super interesting, but it appears generic ("modern vehicles"). My 2017 PM definately doesn't have a hall-effect sensor on the negative-ground battery cable. Apparently not quite as "smart" as that. C- maybe?The Promaster alternator is controlled by the van's computer. It uses a current and temperature sensor on the battery to change the alternator output/voltage. It's not a "smart" alternator by the definition of B2B manufacturers but it is computer controlled. It depends on battery condition and temperature but generally stays in a battery friendly voltage range that allows for split charging and voltage activated B2B chargers.

IMO it works really well. It won't let the smoke out like that staged Victron video and it doesn't play games that are hard on the battery to fool the EPA numbers. The voltages on our van are spot on to keep a lead acid battery at 100% SOC without overcharging.

Here's an article on how it works:

Test of ECU-controlled charging system

An ECU-controlled alternator test is carried out on modern vehicles where there is an intelligent power supply control system. An electronic control unit (ECU) controls the alternator operation. ECU monitors the needs of the vehicle’s electrical system and, based on that, can regulate the output voltage alternator within wide limits (12.7 – 15.5 V) via the rotor power supply. Also, ECU can increase engine idle speed when the alternator is overloaded.

The engine ECU controls the operation of the alternator based on the data obtained from the sensor on the minus terminal of the battery. The sensor on the minus terminal is in the form of a current clamp (Hall sensor) that encompasses the minus cable or the voltage divider (shunt) on the terminal and measures the strength of the charging and discharging current of the battery. It often contains a temperature sensor and can measure the battery temperature. It sends data to the engine ECU via the LIN or CAN network.

![Battery current sensors Battery current sensors]()

Battery current sensors in the form of current clamps or voltage dividers

The ECU engine determines the current state of the power system based on data on the size of the charging and discharging current, the network voltage, and the battery temperature (measured or estimated). It recognizes several modes and regulates the power supply to the rotor windings using PWM. The size of the PWM power supply determines the strength of the magnetic field and the size of the alternator output voltage.

![Image]()

ECU-controlled alternator

When the error light comes on or the operation of the power supply system is suspected, diagnostics are first performed by reading the error codes. If errors are stored, based on the error code and operating instructions, we approach finding the fault. The check can include the alternator, the current sensor, the wires with the connectors, the battery, and finally the ECU engine.

The output voltage from the alternator, battery charge and discharge current, PWM regulation, sensor power, and ECU condition can be checked by measurement. All parameters are monitored via the actual values on the diagnostic device which are visible from the ECU side. In parallel, the same parameters are measured with measuring devices such as an ammeter (current clamp), voltmeter, and oscilloscope recording of PWM signals.

![Relationship between PWM regulation and alternator output voltage Relationship between PWM regulation and alternator output voltage]()

Relationship between PWM regulation and alternator output voltage

Based on the instructions for checking, diagnostics, reading the actual values on the diagnostic device, measuring the current and voltage, and recording the signal, the condition of the power supply system is determined and the malfunction is detected.

Joined

·

27 Posts

There’s so much misinformation online about alternator charging I really wish I could clear up. There is no temperature sensor on these alternators, they’re standard run of the mill externally regulated alternators. There’s a stator (output) and field wire (input).It uses a current and temperature sensor on the battery to change the alternator output/voltage.

With lithium and no temperature compensation on the alternator likely your diodes will melt or bearing will seize and you’ll toss a belt but I’m only speculating here admittedly, maybe these things will handle it but it’s not within specs.

I watched mine easily hit 150C at the stator which is well above normal or even extreme operating temperatures, I shut off charging (I have TVS diodes so no harm from high voltage) and it goes back down to 100C.

The temp sensor is on the battery and is used to adjust the target voltage. If the battery is cold it can be as high as 14.9v and in the summer it’s around 14v. You are correct, the computer does not know the alternator temp. Sorry if I was unclear about that.There’s so much misinformation online about alternator charging I really wish I could clear up. There is no temperature sensor on these alternators, they’re standard run of the mill externally regulated alternators. There’s a stator (output) and field wire (input).

With lithium and no temperature compensation on the alternator likely your diodes will melt or bearing will seize and you’ll toss a belt but I’m only speculating here admittedly, maybe these things will handle it but it’s not within specs.

I watched mine easily hit 150C at the stator which is well above normal or even extreme operating temperatures, I shut off charging (I have TVS diodes so no harm from high voltage) and it goes back down to 100C.

Our van has been charging 1,200ah of lithium directly connected to the alternator. The 20’ of wire and ohms law is the only thing keeping the alternator from self destructing. At idle when the alternator would really get hot this setup is probably a little easier on the alternator than a large B2B, in fact the house batteries hold up the van battery voltage and discharge briefly when the cooling fans come on and the computer/regulator slowly ramps up the alternator.

I plan to rock the direct charge until the warranty is up and then replace the belt, tensioner pulleys, and alternator with an OEM 220a.

i have nothing against B2B, I just used the blue sea stuff I already had. Now that Victron has a more efficient charger I may make the switch once I get around to installing the solar and don’t need all the charging I can get.

Where on the battery?temp sensor is on the battery and is used to adjust the target voltage.

Joined

·

27 Posts

Yea there’s no thermistor/probe in the battery box on my van, I do wonder if it exists though because there are output parameters for in AlphaOBD.Where on the battery?

There definitely must be some form of temperature compensation; even the old mechanical regulators had that. Maybe they figured that some other temperature sensor is a good proxy for battery temperature, or maybe the thermistor is in the ECU itself.Yea there’s no thermistor/probe in the battery box on my van, I do wonder if it exists though because there are output parameters for in AlphaOBD.

I don’t remember, it’s been a year or so since I ran the wires there.

The computer definitely knows (or is really good at estimating) the battery temp because it sets the voltage at the high end of a lead acid charge voltage for the given temp. I have to disable the ground on the charge relay at 14.5v because the van will reach as high as 15v when it’s really cold outside. In the summer it’s much lower.

It was not Rams intention but it helps lower the load on the alternator when direct charging in hot weather. It will have the opposite effect on B2B chargers causing the amp draw to increase.

The computer definitely knows (or is really good at estimating) the battery temp because it sets the voltage at the high end of a lead acid charge voltage for the given temp. I have to disable the ground on the charge relay at 14.5v because the van will reach as high as 15v when it’s really cold outside. In the summer it’s much lower.

It was not Rams intention but it helps lower the load on the alternator when direct charging in hot weather. It will have the opposite effect on B2B chargers causing the amp draw to increase.

Hi. Can you explain how to do that?

There are dozens of posts on it already, they just require some digging. Sometimes you can find them easier with Google than the forums own search feature.

You can run up to a 2/0awg cable from the starter battery to the back of the van. Split charging with a battery isolator has fallen out of favor and requires far more electrical knowledge and careful design than a battery to battery charger. The B2B chargers are really good now, that’s the way to go on a new build. If you do use an isolator keep in mind that the wire will need to be sized for the sum of the fuses on both ends since two batteries will be feeding it during a short.

Here is a post on running the wire from the battery to the back of the van.

You can run up to a 2/0awg cable from the starter battery to the back of the van. Split charging with a battery isolator has fallen out of favor and requires far more electrical knowledge and careful design than a battery to battery charger. The B2B chargers are really good now, that’s the way to go on a new build. If you do use an isolator keep in mind that the wire will need to be sized for the sum of the fuses on both ends since two batteries will be feeding it during a short.

Here is a post on running the wire from the battery to the back of the van.

41 - 57 of 57 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 321K

- members

- 48K

- Since

- 2012

We’re a community forum dedicated to Promaster enthusiasts to discuss mods, camper conversions, diesel, fuel economy, reviews and more!